Introducing... the world’s smallest, smartest, easiest vision system.

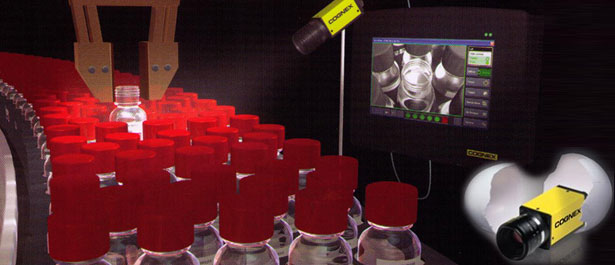

Make it small. Make it smart. Make it easy. That’s what Cognex has achieved with the next-generation In-Sight Micro vision system. In-Sight Micro packs a complete vision system into a remarkably small package that measures just 30mm x 30mm x 60mm. Together with the new, intuitive EasyBuilder™configuration software, and smart VisionView™operator interface display, In-Sight Micro will forever change the way people think about and use vision.

Smallest…

In-Sight Micro vision systems provide world-class performance in the smallest package available. Five new In-Sight Micro models cover a range of price, performance and resolution levels – including a two-megapixel model.

The In-Sight Micro is a full vision system the size of a remote-head camera, ideal for mounting in very tight spaces on robots, production lines and machinery. In addition to small size, the In-Sight Micro provides flexible mounting capability with a unique non-linear calibration tool that enables mounting at angles of up to 45-degrees for hard-to-reach applications.

Smartest…

In-Sight Micro includes the proven Cognex vision tool library to handle the broadest range of vision applications for the widest array of industries. And the new EasyBuilder configuration software makes even the most powerful vision tools easy to use.

EasyBuilder software makes In-Sight Micro remarkably easy to set up and deploy. With a simple point and click approach, EasyBuilder walks users through the process of setting up a vision application, step by step. EasyBuilder eliminates the need for programming, yet provides the flexibility to customize complex applications when needed.

Easiest…

The unique VisionView™ 700 operator interface panel makes it easier than ever to monitor production processes. VisionView automatically detects any Cognex vision system on the network and simultaneously displays information from up to nine vision systems in a tiled view. This allows VisionView to be easily added to any configuration or existing application — without requiring a PC.

A Complete Range of Models

Whether for single-point inspection tasks, or building an entire factory-wide network of vision systems, In-Sight Micro models are available to meet the cost and functionality of the application. And, for system expansion, multiple In-Sight Micro vision systems can be linked to a VisionView display and I/O Accessories. Whether for single-point inspection tasks, or building an entire factory-wide network of vision systems, In-Sight Micro models are available to meet the cost and functionality of the application. And, for system expansion, multiple In-Sight Micro vision systems can be linked to a VisionView display and I/O Accessories.

| Model |

Description |

| 1020 |

Entry-level system with limited tool set* and EasyBuilder interface only (640x480) |

| 1050 |

Entry-level system with limited tool set* plus spreadsheet flexibility (640x480) |

| 1100 |

Best price/performance model with complete tool library (640x480) |

| 1110 |

ID reader-only version (640x480) |

| 1400 |

Highest-speed vision system (640x480) |

| 1410 |

Highest-speed ID reader-only version (640x480) |

| 1403 |

High-resolution vision system in Micro from factor (1600x1200) |

| 1413 |

High-resolution ID reader-only version (1600x1200) |

Whether it's solving a single-point inspection or building an entire factory-wide network of vision systems, the In-Sight product family provides a choice of models to help meet the cost and functionality requirements of the application.

| General-Purpose Vision System |

|

|

In-Sight 5000 Series

These vision systems provide users with the highest level of In-Sight performance, and are the only vision systems available today that provide industrial-grade features as standard.

- Highest-performance models of the In-Sight family

- Die-cast aluminum housing, sealed M12 connectors, and included protective lens cover provide an IP67 (NEMA 6) rating for dust and wash-down Protection

- Includes powerful IDMax™ Data Matrix™ code reading software

- Revolutionary PatMax ® Object location software is optionally available

|

| |

|

|

| General Applications |

High Resolution |

Color |

| In-Sight 5100 |

In-Sight 5401 |

In-Sight 5100C |

Best price/performance

of the In-Sight 5000 Series |

High resolution

(1024/768) imaging |

General color applications |

|

| In-Sight 5400 |

In-Sight 5403 |

In-Sight 5400C |

High performance

In-Sight 5000 model |

Highest resolution (1600/1200) imaging |

Differentiates colors at high production speeds |

|

| In-Sight 5600 |

In-Sight 5603 |

|

Fastest vision system

on the market |

Highest resolution (1600/1200) at fastest speed |

|

|

| |

|

|

| Stainless Steel Vision Systems |

|

|

In-Sight 5400S

- High level of performance

In-Sight 5400CS

- High-speed color on fast production lines

In-Sight 5403S

- Highest resolution (1600X1200) images

|

|

| Remote Head Vision Systems |

|

|

In-Sight 5400R

- In-Sight 5400 performance in the smallest camera head size available

- Ideal for robotic applications, or wherever mounting space is limited

In-Sight 3400

- Standalone configuration (no PC required for setup)

|

|

| Industrial-Grade ID Readers |

|

|

In-Sight 5110

- Provides 1D and 2D decoding for Direct Part Mark Identification. Now with OCV and OCR for verifying and reading alphanumeric strings.

- Supports AIM DPM, ISO and AS 9132 mark quality metrics for code quality assessment.

In-Sight 5410/5410S/5410R/5610

- The 5410 and 5610 models provide all In-Sight 5110 capabilities at higher speeds, with the 5610 providing the highest processing power for high-speed reading and mark quality assessment, and for reading difficult-to-read codes.

- 5410S stainless and 5410R remote head models extend the application versatility of the 5410 model.

In-Sight 5411/5413/5613

- Model 5411 adds high-resolution (1024 x 768) imaging to model 5410 fuctionality; model 5413 adds the highest resolution (1600 x 1200) at the fastest speed.

|

|

In-Sight Vision Tools

The industry-leading Cognex vision tool library provides reliable, repeatable performance in even the most challenging vision applications.

Powerful Location Tools PatMax

If a vision system can’t repeatably locate parts because of wide variations in part orientation, size and appearance, then vision inspection yield and reliability will be significantly reduced.

These variations include:

- Part contrast

- Multiple parts

- Changes in lighting

- Image focus

- Degraded appearance

- Partially-hidden parts

PatMax, the industry’s performance standard for part and feature location software, utilizes advanced geometric pattern matching technology to reliably and accurately locate parts. Even under the above conditions, this tool can significantly reduce or eliminate fixturing requirements and cost. For locating parts or features, PatMax provides the maximum vision inspection yield and reliability available in a vision system. PatMax is optionally available on all general-purpose In-Sight vision systems.

Breakthrough Code Reading IDMax

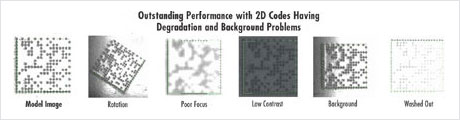

2D Data Matrix code reading in Direct Part Mark Identification (DPMI) applications is an increasingly important part of manufacturing processes. An unreadable code may stop production, and can result in the part not being processed correctly. Standard on most In-Sight models is IDMax, breakthrough Data Matrix reading software based on the patented Cognex PatMax technology. IDMax handles degradation in code appearance, such as those shown below, to deliver the consistently high read rates that are key to the success of part traceability programs.

|